Date:22/02/16

Researchers at Drexel and the Paul Sabatier universities have managed to embed mini supercapacitors directly inside a microchip to enable electronics that are even smaller, last longer, and have more power to feed on.

Researchers at Drexel and the Paul Sabatier universities have managed to embed mini supercapacitors directly inside a microchip to enable electronics that are even smaller, last longer, and have more power to feed on.

The study was led by Yury Gogotsi and Patrice Simon and is the culmination of a more than five-year effort in which the scientists, after developing their tiny energy storage devices, have now managed to fit them inside silicon chips using methods that they say can easily integrate with existing chip manufacturing techniques.

"We set a lofty goal of not just making an energy storage device as small as a microchip," said Simon, "but actually making an energy storage device that is part of the microchip and to do it in a way that is easily integrated into current silicon chip manufacturing processes."

The scientists opted to store on-chip energy on micro-supercapacitors rather than miniature batteries. Current supercapacitors store less than a tenth the energy per unit volume of lithium-ion batteries, but they provide higher power outputs and are much more durable. For most applications, the team's vision is not to replace batteries with supercapacitors altogether, but rather to combine the two to get the best out of both worlds.

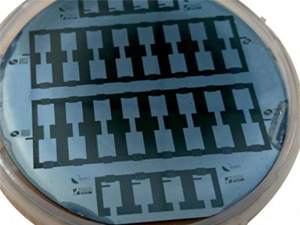

The tiny supercapacitors are made from thin, porous carbon films deposited directly on top of a silicon wafer, with current collectors made of titanium carbide (TiC). Characteristics like resistivity, thickness and mechanical stress of the carbon film can be tweaked by changing manufacturing parameters to fit specific applications and chip designs.

According to the researchers, the result is much more promising for a wide range of applications than the more common route of focusing on micro-batteries.

"Going down to the micro-scale, you need high power in smartphones and other electronic devices, and micro-batteries suffer to meet this power demand," said Simon. Our micro-supercapacitors can do it. Moreover, now that we developed a fabrication process that can be integrated on a chip, compatible with the processes of the semiconductor industry, it becomes easy to place micro-supercapacitors in electronic devices, making the power source more compact – or, you can put more in the same volume."

Micro-supercapacitors store energy directly inside a chip

Researchers at Drexel and the Paul Sabatier universities have managed to embed mini supercapacitors directly inside a microchip to enable electronics that are even smaller, last longer, and have more power to feed on.

Researchers at Drexel and the Paul Sabatier universities have managed to embed mini supercapacitors directly inside a microchip to enable electronics that are even smaller, last longer, and have more power to feed on.The study was led by Yury Gogotsi and Patrice Simon and is the culmination of a more than five-year effort in which the scientists, after developing their tiny energy storage devices, have now managed to fit them inside silicon chips using methods that they say can easily integrate with existing chip manufacturing techniques.

"We set a lofty goal of not just making an energy storage device as small as a microchip," said Simon, "but actually making an energy storage device that is part of the microchip and to do it in a way that is easily integrated into current silicon chip manufacturing processes."

The scientists opted to store on-chip energy on micro-supercapacitors rather than miniature batteries. Current supercapacitors store less than a tenth the energy per unit volume of lithium-ion batteries, but they provide higher power outputs and are much more durable. For most applications, the team's vision is not to replace batteries with supercapacitors altogether, but rather to combine the two to get the best out of both worlds.

The tiny supercapacitors are made from thin, porous carbon films deposited directly on top of a silicon wafer, with current collectors made of titanium carbide (TiC). Characteristics like resistivity, thickness and mechanical stress of the carbon film can be tweaked by changing manufacturing parameters to fit specific applications and chip designs.

According to the researchers, the result is much more promising for a wide range of applications than the more common route of focusing on micro-batteries.

"Going down to the micro-scale, you need high power in smartphones and other electronic devices, and micro-batteries suffer to meet this power demand," said Simon. Our micro-supercapacitors can do it. Moreover, now that we developed a fabrication process that can be integrated on a chip, compatible with the processes of the semiconductor industry, it becomes easy to place micro-supercapacitors in electronic devices, making the power source more compact – or, you can put more in the same volume."

Views: 798

©ictnews.az. All rights reserved.Similar news

- The mobile sector continues its lead

- Facebook counted 600 million active users

- Cell phone testing laboratory is planned to be built in Azerbaijan

- Tablets and riders outfitted quickly with 3G/4G modems

- The number of digital TV channels will double to 24 units

- Tax proposal in China gets massive online feedback

- Malaysia to implement biometric system at all entry points

- Korea to build Green Technology Centre

- Cisco Poised to Help China Keep an Eye on Its Citizens

- 3G speed in Azerbaijan is higher than in UK

- Government of Canada Announces Investment in Green Innovation for Canada

- Electric cars in Azerbaijan

- Dominican Republic Govt Issues Cashless Benefits

- Spain raises €1.65bn from spectrum auction

- Camden Council boosts mobile security