Date:28/10/16

A new method that uses 3D printing to fabricate permanent magnets with specific, pre-determined magnetic-field shapes has been created by researchers at the Technische Universität Wien (TU Wien) in Austria. Their new technique allows for the production of complex forms of magnets, with precisely customised fields – these are especially required to create devices such magnetic sensors.

A new method that uses 3D printing to fabricate permanent magnets with specific, pre-determined magnetic-field shapes has been created by researchers at the Technische Universität Wien (TU Wien) in Austria. Their new technique allows for the production of complex forms of magnets, with precisely customised fields – these are especially required to create devices such magnetic sensors.

"We often require special magnetic fields, with field lines arranged in a very specific way – such as a magnetic field that is relatively constant in one direction, but which varies in strength in another direction," explains Dieter Suess, head of the University's Christian-Doppler Advanced Magnetic Sensing and Materials laboratory.

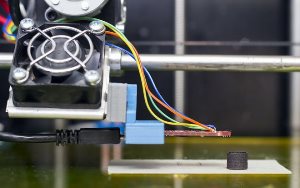

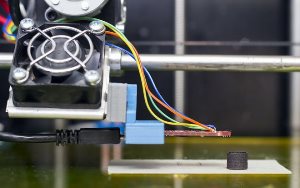

For this to be possible, the magnets need to be produced with a specific geometric form – something the TU Wien team do on a computer, adjusting its shape until all requirements for its magnetic field are met. The design is then implemented via a special 3D printer, created by the team, which can handle magnetic materials. The magnet printer uses specially produced filaments of magnetic micro granulate, which is held together by a polymer binding material. The resulting object is made up of roughly 90% magnetic material and 10% plastic.

Finally, the object is exposed to a strong external magnetic field, converting it into a permanent magnet. The team says its new process is fast, cost-effective and offers new possibilities including using different materials within a single magnet to create a smooth transition between strong and weak magnetism. The research is published in Applied Physics Letters.

The first 3D printer making magnets has been created in Austria

A new method that uses 3D printing to fabricate permanent magnets with specific, pre-determined magnetic-field shapes has been created by researchers at the Technische Universität Wien (TU Wien) in Austria. Their new technique allows for the production of complex forms of magnets, with precisely customised fields – these are especially required to create devices such magnetic sensors.

A new method that uses 3D printing to fabricate permanent magnets with specific, pre-determined magnetic-field shapes has been created by researchers at the Technische Universität Wien (TU Wien) in Austria. Their new technique allows for the production of complex forms of magnets, with precisely customised fields – these are especially required to create devices such magnetic sensors."We often require special magnetic fields, with field lines arranged in a very specific way – such as a magnetic field that is relatively constant in one direction, but which varies in strength in another direction," explains Dieter Suess, head of the University's Christian-Doppler Advanced Magnetic Sensing and Materials laboratory.

For this to be possible, the magnets need to be produced with a specific geometric form – something the TU Wien team do on a computer, adjusting its shape until all requirements for its magnetic field are met. The design is then implemented via a special 3D printer, created by the team, which can handle magnetic materials. The magnet printer uses specially produced filaments of magnetic micro granulate, which is held together by a polymer binding material. The resulting object is made up of roughly 90% magnetic material and 10% plastic.

Finally, the object is exposed to a strong external magnetic field, converting it into a permanent magnet. The team says its new process is fast, cost-effective and offers new possibilities including using different materials within a single magnet to create a smooth transition between strong and weak magnetism. The research is published in Applied Physics Letters.

Views: 649

©ictnews.az. All rights reserved.Similar news

- The mobile sector continues its lead

- Facebook counted 600 million active users

- Cell phone testing laboratory is planned to be built in Azerbaijan

- Tablets and riders outfitted quickly with 3G/4G modems

- The number of digital TV channels will double to 24 units

- Tax proposal in China gets massive online feedback

- Malaysia to implement biometric system at all entry points

- Korea to build Green Technology Centre

- Cisco Poised to Help China Keep an Eye on Its Citizens

- 3G speed in Azerbaijan is higher than in UK

- Government of Canada Announces Investment in Green Innovation for Canada

- Electric cars in Azerbaijan

- Dominican Republic Govt Issues Cashless Benefits

- Spain raises €1.65bn from spectrum auction

- Camden Council boosts mobile security