Date:02/02/16

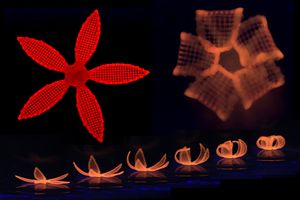

3D printed flower-like objects that change in time based on a pre-programmed pattern have been created by American researchers.

3D printed flower-like objects that change in time based on a pre-programmed pattern have been created by American researchers.

The researchers described the technology as adding a fourth dimension to 3D printing. In its essence, the technology does exactly what plants and flowers do in nature – they change their shapes based on external stimuli. And similarly to plants, the key ingredient for the 4D-printed hydrogel composite structures to change their shape is water.

To enable the 3D printed objects to mimic flowers, the scientists had to go deeper and create a material that actually acts in a similar fashion to the natural tissues of plants. They incorporated cellulose fibrils into the hydrogel that have a similar microstructure to the tissues of leaves, tendrils and blossoms. This microstructure allows the plants to promptly change their shape based on environmental factors such as temperature or humidity.

The cellulose fibrils were incorporated into the objects already during the 3D printing process. These fibrils make the hydrogel swell or become stiff based on the external factors. Elaborate mathematical modelling enabled the researchers to precisely control the swelling and stiffness.

In future, the team hopes, the technology could be used to create smart textiles and soft electronics with novel capabilities or serve for the development of innovative biomedical devices.

Fourth dimension added to 3D printing

3D printed flower-like objects that change in time based on a pre-programmed pattern have been created by American researchers.

3D printed flower-like objects that change in time based on a pre-programmed pattern have been created by American researchers.The researchers described the technology as adding a fourth dimension to 3D printing. In its essence, the technology does exactly what plants and flowers do in nature – they change their shapes based on external stimuli. And similarly to plants, the key ingredient for the 4D-printed hydrogel composite structures to change their shape is water.

To enable the 3D printed objects to mimic flowers, the scientists had to go deeper and create a material that actually acts in a similar fashion to the natural tissues of plants. They incorporated cellulose fibrils into the hydrogel that have a similar microstructure to the tissues of leaves, tendrils and blossoms. This microstructure allows the plants to promptly change their shape based on environmental factors such as temperature or humidity.

The cellulose fibrils were incorporated into the objects already during the 3D printing process. These fibrils make the hydrogel swell or become stiff based on the external factors. Elaborate mathematical modelling enabled the researchers to precisely control the swelling and stiffness.

In future, the team hopes, the technology could be used to create smart textiles and soft electronics with novel capabilities or serve for the development of innovative biomedical devices.

Views: 1032

©ictnews.az. All rights reserved.Similar news

- The mobile sector continues its lead

- Facebook counted 600 million active users

- Cell phone testing laboratory is planned to be built in Azerbaijan

- Tablets and riders outfitted quickly with 3G/4G modems

- The number of digital TV channels will double to 24 units

- Tax proposal in China gets massive online feedback

- Malaysia to implement biometric system at all entry points

- Korea to build Green Technology Centre

- Cisco Poised to Help China Keep an Eye on Its Citizens

- 3G speed in Azerbaijan is higher than in UK

- Government of Canada Announces Investment in Green Innovation for Canada

- Electric cars in Azerbaijan

- Dominican Republic Govt Issues Cashless Benefits

- Spain raises €1.65bn from spectrum auction

- Camden Council boosts mobile security