Date:16/05/16

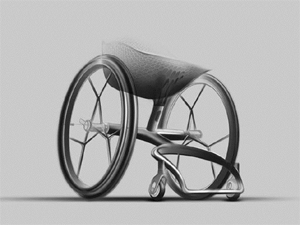

We've seen countless projects look to 3D printing as a manufacturing method, from satellite antennas and titanium rib cages, to printed beaks and jaws. Layer Design's new product takes the fabrication technique's unique ability to quickly provide tailored products, and uses it to build a custom wheelchair with an attractive design.

We've seen countless projects look to 3D printing as a manufacturing method, from satellite antennas and titanium rib cages, to printed beaks and jaws. Layer Design's new product takes the fabrication technique's unique ability to quickly provide tailored products, and uses it to build a custom wheelchair with an attractive design.

The design of the product, known as the GO wheelchair, is the result of research conducted with dozens of wheelchair users, as well as medical professionals, over a six-month period of information gathering. The finished product is designed to help people stop seeing wheelchairs as medical devices, removing that stigma, and presenting them as vehicles to improve lives.

The team listened to the wants and needs of the users, and tallied those desires with practical advice from the medical professionals. The result is the GO wheelchair – a lightweight, functional and attractive piece of kit that's built to fit the needs of various users with different disabilities.

The key element of the product, which is set to be officially launched at the Clerkenwell Design week in London later this month, is its made-to-measure nature – something that would have been more difficult, and a lot more expensive without 3D printing. Specifically, there are two custom-made pieces – the seat and the foot bay – which are built to accurately fit the user's body shape, weight and their disability.

The company maps the user's biometric information, ensuring that each chair is a good fit. The seat is printed from a semi-transparent resin combined with thermoplastic polyurethane for elasticity. Its exact placement is also adjusted based on the body mapping data, ensuring that the centre of gravity is correct.

The geometry of the 3D-printed foot bay, which is constructed from titanium, is built to fit the user's leg length, sitting position and foot shape, and features an anti-slip finish.

Elsewhere, the frame of the chair is built from titanium, with a simple design that cuts down the number of struts to a minimum, lowering the visual weight of the chair. The wheels are also lightweight, with carbon fibre spokes and moulded push-grip rims. The company will also make gloves designed specifically for the chair, featuring a surface that's designed to easily lock in to the push-grip rims, making it easier for users to self-propel.

Colour selection and optional extras (transfer bars, push bars and wheel guards) are selected via an app designed by the company, through which the final order is placed.

Users should be able to get their hands on their custom-built chair fairly quickly after that point, with the company claiming that it can complete the manufacture and delivery process in less than two weeks. That's significantly quicker than other customised wheelchairs, which take between six and eight weeks to turn up the door.

There's no word yet on exactly how much the GO wheelchair will cost, or when the first units will ship. Expect to hear more when the product is launched later this month at the Clerkenwell Design Week in London.

World's first consumer 3D-printed wheelchair set to launch in London

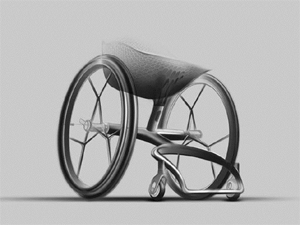

We've seen countless projects look to 3D printing as a manufacturing method, from satellite antennas and titanium rib cages, to printed beaks and jaws. Layer Design's new product takes the fabrication technique's unique ability to quickly provide tailored products, and uses it to build a custom wheelchair with an attractive design.

We've seen countless projects look to 3D printing as a manufacturing method, from satellite antennas and titanium rib cages, to printed beaks and jaws. Layer Design's new product takes the fabrication technique's unique ability to quickly provide tailored products, and uses it to build a custom wheelchair with an attractive design.The design of the product, known as the GO wheelchair, is the result of research conducted with dozens of wheelchair users, as well as medical professionals, over a six-month period of information gathering. The finished product is designed to help people stop seeing wheelchairs as medical devices, removing that stigma, and presenting them as vehicles to improve lives.

The team listened to the wants and needs of the users, and tallied those desires with practical advice from the medical professionals. The result is the GO wheelchair – a lightweight, functional and attractive piece of kit that's built to fit the needs of various users with different disabilities.

The key element of the product, which is set to be officially launched at the Clerkenwell Design week in London later this month, is its made-to-measure nature – something that would have been more difficult, and a lot more expensive without 3D printing. Specifically, there are two custom-made pieces – the seat and the foot bay – which are built to accurately fit the user's body shape, weight and their disability.

The company maps the user's biometric information, ensuring that each chair is a good fit. The seat is printed from a semi-transparent resin combined with thermoplastic polyurethane for elasticity. Its exact placement is also adjusted based on the body mapping data, ensuring that the centre of gravity is correct.

The geometry of the 3D-printed foot bay, which is constructed from titanium, is built to fit the user's leg length, sitting position and foot shape, and features an anti-slip finish.

Elsewhere, the frame of the chair is built from titanium, with a simple design that cuts down the number of struts to a minimum, lowering the visual weight of the chair. The wheels are also lightweight, with carbon fibre spokes and moulded push-grip rims. The company will also make gloves designed specifically for the chair, featuring a surface that's designed to easily lock in to the push-grip rims, making it easier for users to self-propel.

Colour selection and optional extras (transfer bars, push bars and wheel guards) are selected via an app designed by the company, through which the final order is placed.

Users should be able to get their hands on their custom-built chair fairly quickly after that point, with the company claiming that it can complete the manufacture and delivery process in less than two weeks. That's significantly quicker than other customised wheelchairs, which take between six and eight weeks to turn up the door.

There's no word yet on exactly how much the GO wheelchair will cost, or when the first units will ship. Expect to hear more when the product is launched later this month at the Clerkenwell Design Week in London.

Views: 481

©ictnews.az. All rights reserved.Similar news

- Azerbaijani project to monitor disease via mobile phones

- Innovative educational system to be improved under presidential decree

- NTRC prolongs license of two TV and radio organizations for 6 years

- Azerbaijan establishes e-registry for medicines

- Azerbaijani museum introduces e-guide

- Nar Mobile opens “Nar Dunyasi” sales and service center in Siyazan city

- International conference on custom electronic services held in Baku

- OIC secretary general to attend COMSTECH meeting in Baku

- Azerbaijan develops earthquake warning system

- New law to regulate transition to digital broadcasting in Azerbaijan

- Azerbaijani State Social Protection Fund introduces electronic digital signature

- Intellectual traffic management system in Baku to be commissioned in December

- Tax Ministry of Azerbaijan started receiving video-addresses

- World Bank recommends Azerbaijan to speed up e-service introduction in real estate

- Azerbaijan to shift to electronic registration of real estate