Date:09/12/16

As sensors, computers, actuators, and batteries decrease in size and increase in efficiency, it becomes possible to make robots much smaller without sacrificing a whole lot of capability. There’s a lower limit on usefulness, however, if you’re making a robot that needs to interact with humans or human-scale objects. You can continue to leverage shrinking components if you make robots that are modular: in other words, big robots that are made up of lots of little robots.

As sensors, computers, actuators, and batteries decrease in size and increase in efficiency, it becomes possible to make robots much smaller without sacrificing a whole lot of capability. There’s a lower limit on usefulness, however, if you’re making a robot that needs to interact with humans or human-scale objects. You can continue to leverage shrinking components if you make robots that are modular: in other words, big robots that are made up of lots of little robots.

In some ways, it’s more complicated to do this, because if one robot is complicated, n robots tend to be complicatedn. If you can get all of the communication and coordination figured out, though, a modular system offers tons of advantages: robots that come in any size you want, any configuration you want, and that are exceptionally easy to repair and reconfigure on the fly.

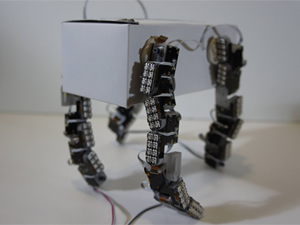

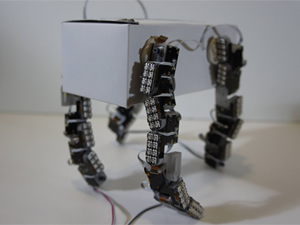

MIT’s ChainFORM is an interesting take on this idea: it’s an evolution of last year’s LineFORM multifunctional snake robot that introduces modularity to the system, letting you tear of a strip of exactly how much robot you need, and then reconfigure it to do all kinds of things.

As sensors, computers, actuators, and batteries decrease in size and increase in efficiency, it becomes possible to make robots much smaller without sacrificing a whole lot of capability. There’s a lower limit on usefulness, however, if you’re making a robot that needs to interact with humans or human-scale objects. You can continue to leverage shrinking components if you make robots that are modular: in other words, big robots that are made up of lots of little robots.

In some ways, it’s more complicated to do this, because if one robot is complicated, n robots tend to be complicatedn. If you can get all of the communication and coordination figured out, though, a modular system offers tons of advantages: robots that come in any size you want, any configuration you want, and that are exceptionally easy to repair and reconfigure on the fly.

MIT’s ChainFORM is an interesting take on this idea: it’s an evolution of last year’s LineFORM multifunctional snake robot that introduces modularity to the system, letting you tear of a strip of exactly how much robot you need, and then reconfigure it to do all kinds of things.

MIT Media Lab calls ChainFORM a “shape changing interface,” because it comes from their Tangible Media Group, but if it came from a robotics group, it would be called a “poke-able modular snake robot with blinky lights.” Each ChainFORM module includes touch detection on multiple surfaces, angular detection, blinky lights, and motor actuation via a single servo motor. The trickiest bit is the communication architecture: MIT had to invent something that can automatically determine how many modules there are, and how the modules are connected to each other, while preserving the capability for real-time input and output. Since the relative position and orientation of each module is known at all times, you can do cool things like make a dynamically reconfigurable display that will continue to function (or adaptively change its function) even as you change the shape of the modules.

ChainFORM is not totally modular, in the sense that each module is not completely self-contained at this point: it’s tethered for power, and for overall control there’s a master board that interfaces with a computer over USB. The power tether also imposes a limit on the total number of modules that you can use at once because of the resistance of the connectors: no more than 32, unless you also connect power from the other end. The modules are still powerful, though: each can exert 0.8 kg/cm of torque, which is enough to move small things. It won’t move your limbs, but you’ll feel it trying, which makes it effective for haptic feedback applications, and able to support (and move) much of its own weight.

If it looks like ChainFORM has a lot of potential for useful improvements, that’s because ChainFORM has a lot of potential for useful improvements, according to the people who are developing useful improvements for it. They want to put displays on every surface, and increase their resolution. They want more joint configurations for connecting different modules and a way to split modules into different branches. And they want the modules to be able to self-assemble, like many modular robots are already able to do. The researchers also discuss things like adding different kinds of sensor modules and actuator modules, which would certainly increase the capability of the system as a whole without increasing the complexity of individual modules, but it would also make ChainFORM into more of a system of modules, which is (in my opinion) a bit less uniquely elegant than what ChainFORM is now.

MIT's Modular Robotic Chain Is Whatever You Want It To Be

As sensors, computers, actuators, and batteries decrease in size and increase in efficiency, it becomes possible to make robots much smaller without sacrificing a whole lot of capability. There’s a lower limit on usefulness, however, if you’re making a robot that needs to interact with humans or human-scale objects. You can continue to leverage shrinking components if you make robots that are modular: in other words, big robots that are made up of lots of little robots.

As sensors, computers, actuators, and batteries decrease in size and increase in efficiency, it becomes possible to make robots much smaller without sacrificing a whole lot of capability. There’s a lower limit on usefulness, however, if you’re making a robot that needs to interact with humans or human-scale objects. You can continue to leverage shrinking components if you make robots that are modular: in other words, big robots that are made up of lots of little robots.In some ways, it’s more complicated to do this, because if one robot is complicated, n robots tend to be complicatedn. If you can get all of the communication and coordination figured out, though, a modular system offers tons of advantages: robots that come in any size you want, any configuration you want, and that are exceptionally easy to repair and reconfigure on the fly.

MIT’s ChainFORM is an interesting take on this idea: it’s an evolution of last year’s LineFORM multifunctional snake robot that introduces modularity to the system, letting you tear of a strip of exactly how much robot you need, and then reconfigure it to do all kinds of things.

As sensors, computers, actuators, and batteries decrease in size and increase in efficiency, it becomes possible to make robots much smaller without sacrificing a whole lot of capability. There’s a lower limit on usefulness, however, if you’re making a robot that needs to interact with humans or human-scale objects. You can continue to leverage shrinking components if you make robots that are modular: in other words, big robots that are made up of lots of little robots.

In some ways, it’s more complicated to do this, because if one robot is complicated, n robots tend to be complicatedn. If you can get all of the communication and coordination figured out, though, a modular system offers tons of advantages: robots that come in any size you want, any configuration you want, and that are exceptionally easy to repair and reconfigure on the fly.

MIT’s ChainFORM is an interesting take on this idea: it’s an evolution of last year’s LineFORM multifunctional snake robot that introduces modularity to the system, letting you tear of a strip of exactly how much robot you need, and then reconfigure it to do all kinds of things.

MIT Media Lab calls ChainFORM a “shape changing interface,” because it comes from their Tangible Media Group, but if it came from a robotics group, it would be called a “poke-able modular snake robot with blinky lights.” Each ChainFORM module includes touch detection on multiple surfaces, angular detection, blinky lights, and motor actuation via a single servo motor. The trickiest bit is the communication architecture: MIT had to invent something that can automatically determine how many modules there are, and how the modules are connected to each other, while preserving the capability for real-time input and output. Since the relative position and orientation of each module is known at all times, you can do cool things like make a dynamically reconfigurable display that will continue to function (or adaptively change its function) even as you change the shape of the modules.

ChainFORM is not totally modular, in the sense that each module is not completely self-contained at this point: it’s tethered for power, and for overall control there’s a master board that interfaces with a computer over USB. The power tether also imposes a limit on the total number of modules that you can use at once because of the resistance of the connectors: no more than 32, unless you also connect power from the other end. The modules are still powerful, though: each can exert 0.8 kg/cm of torque, which is enough to move small things. It won’t move your limbs, but you’ll feel it trying, which makes it effective for haptic feedback applications, and able to support (and move) much of its own weight.

If it looks like ChainFORM has a lot of potential for useful improvements, that’s because ChainFORM has a lot of potential for useful improvements, according to the people who are developing useful improvements for it. They want to put displays on every surface, and increase their resolution. They want more joint configurations for connecting different modules and a way to split modules into different branches. And they want the modules to be able to self-assemble, like many modular robots are already able to do. The researchers also discuss things like adding different kinds of sensor modules and actuator modules, which would certainly increase the capability of the system as a whole without increasing the complexity of individual modules, but it would also make ChainFORM into more of a system of modules, which is (in my opinion) a bit less uniquely elegant than what ChainFORM is now.

Views: 651

©ictnews.az. All rights reserved.Similar news

- The mobile sector continues its lead

- Facebook counted 600 million active users

- Cell phone testing laboratory is planned to be built in Azerbaijan

- Tablets and riders outfitted quickly with 3G/4G modems

- The number of digital TV channels will double to 24 units

- Tax proposal in China gets massive online feedback

- Malaysia to implement biometric system at all entry points

- Korea to build Green Technology Centre

- Cisco Poised to Help China Keep an Eye on Its Citizens

- 3G speed in Azerbaijan is higher than in UK

- Government of Canada Announces Investment in Green Innovation for Canada

- Electric cars in Azerbaijan

- Dominican Republic Govt Issues Cashless Benefits

- Spain raises €1.65bn from spectrum auction

- Camden Council boosts mobile security