Date:12/04/17

South Korea’s Electronics and Telecommunications Research Institute said Tuesday it has developed transparent electrodes for organic light-emitting diode displays out of graphene in cooperation with Hanwha Techwin.

South Korea’s Electronics and Telecommunications Research Institute said Tuesday it has developed transparent electrodes for organic light-emitting diode displays out of graphene in cooperation with Hanwha Techwin.

Graphene is considered the thinnest, most flexible and fastest in transferring heat and electricity among exiting materials. As display panels become thinner and lighter, ways to utilize graphene are being studied by many research groups.

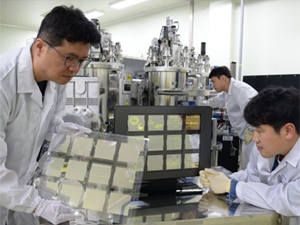

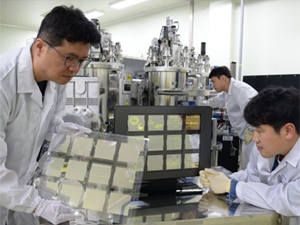

ETRI and Hanwha said their joint research team succeeded in using graphene to replace indium tin oxide, known as ITO, which has been widely used to make transparent electrodes in OLED panels.

ITO is highly fragile, but graphene is flexible and resistant to chipping.

The team used graphene on the largest OLED panel on earth, which is 370 millimeters in length and 470 mm in width. The thickness of the team’s graphene electrode was less than 5 nanometers.

They also developed a process for patterning graphene-based transparent electrodes with specific numbers and shapes on the OLED substrates, which could be applied for developing flexible smart devices in the future.

By using the new material, the commercialization of flexible OLED products can move forward, according to Cho Nam-sung, head of ETRI research team.

“It is meaningful that we are the first to apply graphene to OLED panels,” Cho said. “The technology would help elevate Korea’s OLED panel technology by widening the technology gap with Chinese rivals.”

ETRI began the research four years ago in support of the Ministry of Trade, Industry and Energy. In 2015, the researchers successfully developed a graphene-based OLED panel that is about the size of a coin and about 10 times bigger one last year. Their work was presented at Graphene Conference 2017 held in Barcelona last month.

The team also plans to develop plastic OLED electrodes by next year, and aims to help commercialize flexible and fordable OLED panels in five years.

The display industry welcomed the news, hoping for wider use of the cutting-edge material in producing completely fordable display panels.

LG Display, a leading OLED panel manufacturer, is currently working on development of fordable display panels. The company introduced what it calls a “rollable” OLED panel, referring to a panel that can be rolled up as toilet paper, at the Consumer Electronics Show in January.

“Companies are making similar efforts to develop fordable display panels by minimizing the use of ITO electrodes by applying other materials such as plastics,” said a spokesman at LG Display. “If commercialized soon, the graphene electrode technology would help the industry achieve fordable panels significantly.”

Korea first to use graphene to make OLED panel

South Korea’s Electronics and Telecommunications Research Institute said Tuesday it has developed transparent electrodes for organic light-emitting diode displays out of graphene in cooperation with Hanwha Techwin.

South Korea’s Electronics and Telecommunications Research Institute said Tuesday it has developed transparent electrodes for organic light-emitting diode displays out of graphene in cooperation with Hanwha Techwin.Graphene is considered the thinnest, most flexible and fastest in transferring heat and electricity among exiting materials. As display panels become thinner and lighter, ways to utilize graphene are being studied by many research groups.

ETRI and Hanwha said their joint research team succeeded in using graphene to replace indium tin oxide, known as ITO, which has been widely used to make transparent electrodes in OLED panels.

ITO is highly fragile, but graphene is flexible and resistant to chipping.

The team used graphene on the largest OLED panel on earth, which is 370 millimeters in length and 470 mm in width. The thickness of the team’s graphene electrode was less than 5 nanometers.

They also developed a process for patterning graphene-based transparent electrodes with specific numbers and shapes on the OLED substrates, which could be applied for developing flexible smart devices in the future.

By using the new material, the commercialization of flexible OLED products can move forward, according to Cho Nam-sung, head of ETRI research team.

“It is meaningful that we are the first to apply graphene to OLED panels,” Cho said. “The technology would help elevate Korea’s OLED panel technology by widening the technology gap with Chinese rivals.”

ETRI began the research four years ago in support of the Ministry of Trade, Industry and Energy. In 2015, the researchers successfully developed a graphene-based OLED panel that is about the size of a coin and about 10 times bigger one last year. Their work was presented at Graphene Conference 2017 held in Barcelona last month.

The team also plans to develop plastic OLED electrodes by next year, and aims to help commercialize flexible and fordable OLED panels in five years.

The display industry welcomed the news, hoping for wider use of the cutting-edge material in producing completely fordable display panels.

LG Display, a leading OLED panel manufacturer, is currently working on development of fordable display panels. The company introduced what it calls a “rollable” OLED panel, referring to a panel that can be rolled up as toilet paper, at the Consumer Electronics Show in January.

“Companies are making similar efforts to develop fordable display panels by minimizing the use of ITO electrodes by applying other materials such as plastics,” said a spokesman at LG Display. “If commercialized soon, the graphene electrode technology would help the industry achieve fordable panels significantly.”

Views: 470

©ictnews.az. All rights reserved.Similar news

- The mobile sector continues its lead

- Facebook counted 600 million active users

- Cell phone testing laboratory is planned to be built in Azerbaijan

- Tablets and riders outfitted quickly with 3G/4G modems

- The number of digital TV channels will double to 24 units

- Tax proposal in China gets massive online feedback

- Malaysia to implement biometric system at all entry points

- Korea to build Green Technology Centre

- Cisco Poised to Help China Keep an Eye on Its Citizens

- 3G speed in Azerbaijan is higher than in UK

- Government of Canada Announces Investment in Green Innovation for Canada

- Electric cars in Azerbaijan

- Dominican Republic Govt Issues Cashless Benefits

- Spain raises €1.65bn from spectrum auction

- Camden Council boosts mobile security