Date:08/08/17

The largest apparel producer for sportswear giant Adidas – Chinese firm Tianyuan Garments Company – will introduce fully automated ‘Sewbots’ at its new facilities in Little Rock, China, in a bid to manufacture over 800,000 t-shirts per day.

The largest apparel producer for sportswear giant Adidas – Chinese firm Tianyuan Garments Company – will introduce fully automated ‘Sewbots’ at its new facilities in Little Rock, China, in a bid to manufacture over 800,000 t-shirts per day.

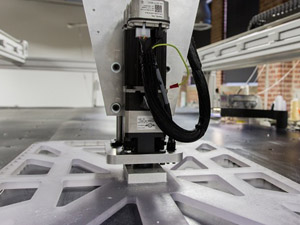

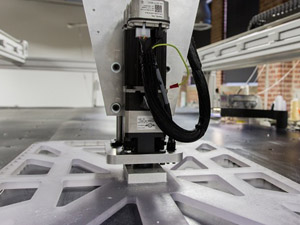

The Sewbots, manufactured by US company SoftWear Automation, are intended to improve production efficiency with a patented computer vision system. The machines use a combination of cameras and needles to track the placement of a fabric before sewing the apparel at a reported higher level of accuracy than the human eye.

The investment is in conjunction with Tianyuan’s pending move to new facilities in Little Rock, China. The company is expected to begin production with the Sewbots by the end of 2018, reported China Daily.

Recent expansive operations by SoftWear Automation, as reported in T.EVO, started following investment by CTW Venture Partners which allowed the company to accelerate its development of Sewbots.

The acquisition of this technology is seen as a cost effective method to often labour-intensive work, and provides an opportunity to ‘near-shore’ manufacturing closer to the consumer.

Textile evolution: Sewbots to produce Adidas apparel

The largest apparel producer for sportswear giant Adidas – Chinese firm Tianyuan Garments Company – will introduce fully automated ‘Sewbots’ at its new facilities in Little Rock, China, in a bid to manufacture over 800,000 t-shirts per day.

The largest apparel producer for sportswear giant Adidas – Chinese firm Tianyuan Garments Company – will introduce fully automated ‘Sewbots’ at its new facilities in Little Rock, China, in a bid to manufacture over 800,000 t-shirts per day.The Sewbots, manufactured by US company SoftWear Automation, are intended to improve production efficiency with a patented computer vision system. The machines use a combination of cameras and needles to track the placement of a fabric before sewing the apparel at a reported higher level of accuracy than the human eye.

The investment is in conjunction with Tianyuan’s pending move to new facilities in Little Rock, China. The company is expected to begin production with the Sewbots by the end of 2018, reported China Daily.

Recent expansive operations by SoftWear Automation, as reported in T.EVO, started following investment by CTW Venture Partners which allowed the company to accelerate its development of Sewbots.

The acquisition of this technology is seen as a cost effective method to often labour-intensive work, and provides an opportunity to ‘near-shore’ manufacturing closer to the consumer.

Views: 414

©ictnews.az. All rights reserved.Similar news

- Azerbaijani project to monitor disease via mobile phones

- Innovative educational system to be improved under presidential decree

- NTRC prolongs license of two TV and radio organizations for 6 years

- Azerbaijan establishes e-registry for medicines

- Azerbaijani museum introduces e-guide

- Nar Mobile opens “Nar Dunyasi” sales and service center in Siyazan city

- International conference on custom electronic services held in Baku

- OIC secretary general to attend COMSTECH meeting in Baku

- Azerbaijan develops earthquake warning system

- New law to regulate transition to digital broadcasting in Azerbaijan

- Azerbaijani State Social Protection Fund introduces electronic digital signature

- Intellectual traffic management system in Baku to be commissioned in December

- Tax Ministry of Azerbaijan started receiving video-addresses

- World Bank recommends Azerbaijan to speed up e-service introduction in real estate

- Azerbaijan to shift to electronic registration of real estate