Date:22/10/18

Lithium-ion batteries power everything from smartphones and tablets to e-cigarettes and electric cars. Until now, manufacturers have had to design their devices around standard battery sizes, and it limits the design options and capacities of consumer devices. But researchers, led by Christopher Reyes and Benjamin Wiley have developed a new method to 3D print lithium-ion batteries in virtually any shape. They report their results in ACS Applied Energy Materials.

Lithium-ion batteries power everything from smartphones and tablets to e-cigarettes and electric cars. Until now, manufacturers have had to design their devices around standard battery sizes, and it limits the design options and capacities of consumer devices. But researchers, led by Christopher Reyes and Benjamin Wiley have developed a new method to 3D print lithium-ion batteries in virtually any shape. They report their results in ACS Applied Energy Materials.

Most lithium-ion batteries on the market are either rectangular or cylindrical. Theoretically, 3D printing technologies can print an entire device, including the battery and structural and electronic components, in almost any shape. However, the problem that has stood in the way of fully 3D printed lithium-ion batteries is that the the polymers used for 3D printing, such as poly(lactic acid) (PLA), are not ionic conductors. Researchers wanted to find a way to print complete lithium-ion batteries using low cost and widely available fused filament fabrication (FFF) 3D printers.

In order to increase the ionic conductivity of PLA, the researchers infused the PLA used in 3D printing with an electrolyte solution. In addition, they incorporated graphene or multi-walled carbon nanotubes into the anode or cathode, respectively to help boost the battery's electrical conductivity.

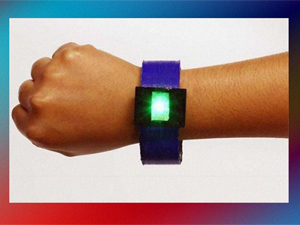

To demonstrate the battery's potential, researchers 3D printed an LED bangle bracelet with an integrated lithium-ion battery. And the bangle battery could power a green LED for about 60 seconds.

The team notes the capacity of the first-generation 3D printed battery is about two orders of magnitude lower than that of commercial batteries, which is too low for practical use. Future work may include developing ways to increase the capacity of 3D printed battery, such as "replacing the polymer-based anode and cathode materials with 3D printable pastes that can accommodate high loadings of active material and can be printed in tandem with a polymer separator and case.

The use of alternative nanomaterials such as reduced graphene oxide may potentially serve as both the conductive filler and active material, eliminating the need for both an inactive conductive material and a low conductivity active material. Alternatively, wrapping the active materials, LTO and LMO, with conductive fillers prior to mixing in the polymer may improve electrical contact to the active materials when they are present at low concentrations in the polymer. These results should benefit those seeking to create energy storage materials and devices that can be 3D printed to create batteries in arbitrary shapes."

New method developed to 3D print lithium-ion batteries in nearly any shape

Lithium-ion batteries power everything from smartphones and tablets to e-cigarettes and electric cars. Until now, manufacturers have had to design their devices around standard battery sizes, and it limits the design options and capacities of consumer devices. But researchers, led by Christopher Reyes and Benjamin Wiley have developed a new method to 3D print lithium-ion batteries in virtually any shape. They report their results in ACS Applied Energy Materials.

Lithium-ion batteries power everything from smartphones and tablets to e-cigarettes and electric cars. Until now, manufacturers have had to design their devices around standard battery sizes, and it limits the design options and capacities of consumer devices. But researchers, led by Christopher Reyes and Benjamin Wiley have developed a new method to 3D print lithium-ion batteries in virtually any shape. They report their results in ACS Applied Energy Materials.Most lithium-ion batteries on the market are either rectangular or cylindrical. Theoretically, 3D printing technologies can print an entire device, including the battery and structural and electronic components, in almost any shape. However, the problem that has stood in the way of fully 3D printed lithium-ion batteries is that the the polymers used for 3D printing, such as poly(lactic acid) (PLA), are not ionic conductors. Researchers wanted to find a way to print complete lithium-ion batteries using low cost and widely available fused filament fabrication (FFF) 3D printers.

In order to increase the ionic conductivity of PLA, the researchers infused the PLA used in 3D printing with an electrolyte solution. In addition, they incorporated graphene or multi-walled carbon nanotubes into the anode or cathode, respectively to help boost the battery's electrical conductivity.

To demonstrate the battery's potential, researchers 3D printed an LED bangle bracelet with an integrated lithium-ion battery. And the bangle battery could power a green LED for about 60 seconds.

The team notes the capacity of the first-generation 3D printed battery is about two orders of magnitude lower than that of commercial batteries, which is too low for practical use. Future work may include developing ways to increase the capacity of 3D printed battery, such as "replacing the polymer-based anode and cathode materials with 3D printable pastes that can accommodate high loadings of active material and can be printed in tandem with a polymer separator and case.

The use of alternative nanomaterials such as reduced graphene oxide may potentially serve as both the conductive filler and active material, eliminating the need for both an inactive conductive material and a low conductivity active material. Alternatively, wrapping the active materials, LTO and LMO, with conductive fillers prior to mixing in the polymer may improve electrical contact to the active materials when they are present at low concentrations in the polymer. These results should benefit those seeking to create energy storage materials and devices that can be 3D printed to create batteries in arbitrary shapes."

Views: 373

©ictnews.az. All rights reserved.Similar news

- Azerbaijani project to monitor disease via mobile phones

- Innovative educational system to be improved under presidential decree

- NTRC prolongs license of two TV and radio organizations for 6 years

- Azerbaijan establishes e-registry for medicines

- Azerbaijani museum introduces e-guide

- Nar Mobile opens “Nar Dunyasi” sales and service center in Siyazan city

- International conference on custom electronic services held in Baku

- OIC secretary general to attend COMSTECH meeting in Baku

- Azerbaijan develops earthquake warning system

- New law to regulate transition to digital broadcasting in Azerbaijan

- Azerbaijani State Social Protection Fund introduces electronic digital signature

- Intellectual traffic management system in Baku to be commissioned in December

- Tax Ministry of Azerbaijan started receiving video-addresses

- World Bank recommends Azerbaijan to speed up e-service introduction in real estate

- Azerbaijan to shift to electronic registration of real estate